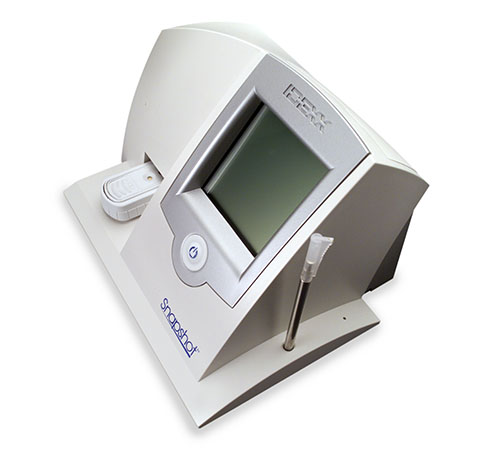

Faced with an aging image‐reader platform and rapidly evolving FDA mandates for antibiotic screening in milk, IDEXX partnered with Eclipse to accelerate the development of a next-generation residue analyzer. Under a tight timeline driven by new regulatory thresholds, Eclipse leveraged its cross-disciplinary expertise to reimagine the device architecture, moving beyond legacy optics and outdated software.

Through a rapid-cycle design process, Eclipse delivered a robust, modular system featuring advanced sensor arrays and automated analysis algorithms that exceed the latest FDA sensitivity requirements. The streamlined user interface and automated sample handling workflow minimize operator steps—ensuring reliable, on-farm testing with results in under 10 minutes.

By outsourcing to Eclipse, IDEXX not only met the critical compliance deadline but also gained a scalable platform poised for future upgrades. The new Snapshot Analyzer sets a new industry benchmark for speed, accuracy, and ease of use in antibiotic residue testing—helping dairy producers maintain product safety and regulatory confidence.

To ground the Snapshot Analyzer in real-world workflows, Eclipse kicked off the project with immersive site visits to multiple dairy farms and on-site milk testing facilities. Designers and Engineers shadowed farm technicians as they collected, labeled, and analyzed milk samples—mapping every step from sample receipt to result reporting. Through contextual inquiry and hands-on observation, the team identified key pain points: cumbersome sample transfers, inconsistent temperature control during handling, and complex data-entry steps that slowed throughput.

Armed with these insights, Eclipse led collaborative workshops with dairy operators, quality-assurance managers, and regulatory specialists to translate field observations into a clear set of design requirements. Priorities included a portable, rugged chassis suitable for barn environments, integrated temperature stabilization for sample integrity, and a simplified, icon-driven interface to minimize training. Early prototype sketches and mockups were iterated rapidly—each informed by direct user feedback on ergonomics, workflow integration, and cleaning protocols—to ensure the final system would streamline on-farm testing without disrupting daily operations. This user-centered research and planning effort laid the foundation for a device that meets both FDA mandates and the practical needs of dairy producers.