Innovative companies often work on a phase-gate process for getting funding to continue their development process, and it’s an area we are very familiar with. To continue development, or to do a pre-submission trial, companies need representative product, but are not ready to go to full production as they are still in a refinement phase.

We know this, and are in a position to help in many ways. A phone or tablet running Android can be repurposed to get a feasibility prototype functional for an application with screen and communications built in, and it is possible to get real molded parts quickly and for less investment than a few years ago.

This means that we can quickly make as few as twenty fully working prototypes for field trials and verifying processes, helping to get the development process moving faster than ever before.

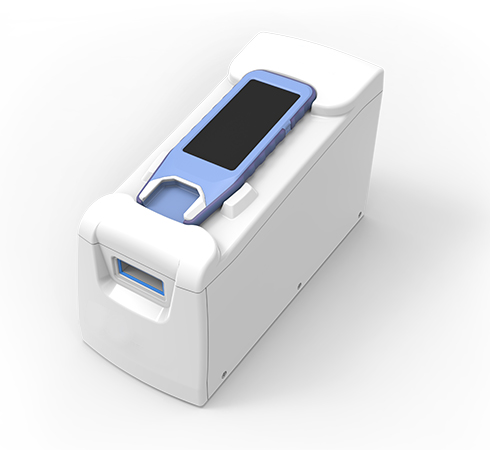

NanoDx wanted to be able to test their console and Nano Biosensor in real situations to get valuable knowledge for the commercialization of their point-of-care diagnostic machine, and knew that they needed realistic prototypes with a limited manufacturing run.

We have designed many bench top and hand held devices for use in hospitals, and knew many of the unique constraints these environments have.

We helped them with the design, engineering and prototyping of both the initial handheld device used for getting patient information, and the console that analyzes the blood sample.

For the hand held device, by using a modified cell phone running Android allowed us to speed up the process by not having to design circuit boards, screens, antennas and battery chargers as they were all included, and could concentrate on a simple circuit that communicates via the USB port. It’s also a lot quicker to create a program for Android than it is to create one from scratch.

We designed a simple enclosure that would hold the diagnostic cassette while being transported to the console, with an oversized bumper to protect it from knocks and being dropped.

The console was designed to have an internal stainless steel frame to hold everything securely, and a set of molded covers for a skin.

Originally we were going to use cast urethane parts for the handheld and console, but a cost analysis showed that molding the parts was a similar price, and yielded better parts with materials more suitable for use in a hospital, and the aggressive chemicals used for cleaning.

As part of our prototyping service we assembled units and also manufactured the wiring looms for the client.