Our manufacturing transition phase bridges the gap between refined product design and full-scale production. Leveraging both domestic and overseas partners, we establish a flexible and resilient manufacturing strategy tailored to cost, volume, and regulatory needs.

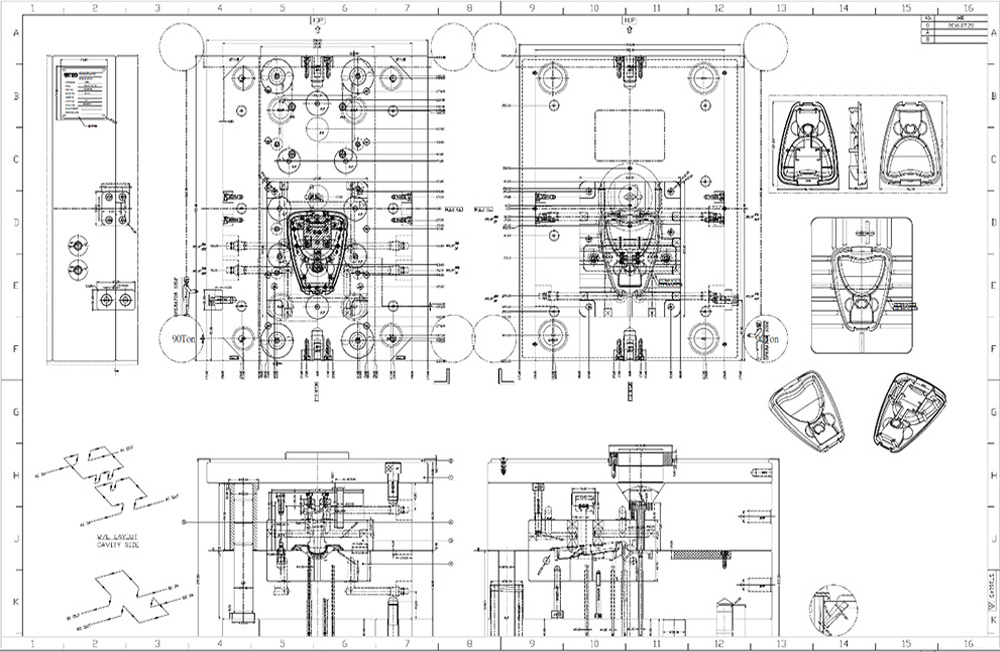

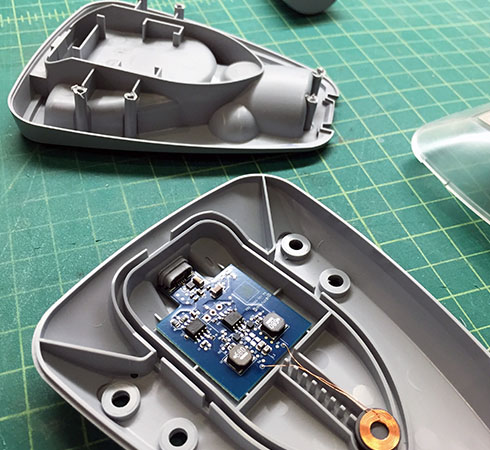

During this phase, we focus on translating the final design into scalable, repeatable, and controlled manufacturing processes. Our team develops and documents custom assembly methods, inspection protocols, and tooling/fixtures designed to streamline production while maintaining quality and compliance.

A key differentiator is our ability to identify and develop intellectual property within the manufacturing process itself. This includes proprietary fixtures, assembly techniques, and test methods that improve efficiency and yield. These elements are owned by you, not the manufacturing partner—giving you strategic leverage and long-term value.

Once the process is validated, we provide the selected manufacturing partner, whether domestic or overseas, with a complete and transferable production package. This includes:

Services include but are not limited to:

“Eclipse took our initial ideas and transformed them into something beyond what we could have imagined. Every detail was thoughtfully considered, and their design work helped bring our vision to life in a way that felt fresh and unique.”

Learn how we quickly developed a new product for the life science sector.

Designed and developed by Eclipse Product Development, the AcceleDent® Optima™ is the first and only FDA-cleared Vibratory Orthodontic Device clinically proven to speed up orthodontic treatment by …